SOLE joins Kongsberg Technology Cluster

Intro

High-tech expertise, innovation, and collaboration.

Sole AS is now a member of the Kongsberg Technology Cluster, becoming part of a community defined by high-tech expertise, innovation, and collaboration.

We want to build closer relationships with neighbouring companies, collaborate across sectors, and connect with the technology and knowledge that exists in the Kongsberg environment,’ says Tom Johansen, Sales and Marketing at Sole AS.

About KTC

About Kongsberg Technology Cluster

Kongsberg Technology Cluster is a network of 20 technology companies, industrial enterprises, research environments, and educational institutions. The goal is to become more competitive through knowledge sharing, joint development projects, and increased access to relevant expertise. Being a member means becoming part of an active, tech-focused network where collaboration and innovation are at the core.

Looking ahead (1)

Looking ahead

For Sole AS, the membership is primarily about looking ahead and is an important step in their efforts to establish a more diversified foundation.

One of the reasons we applied for membership is the current global situation. We want to be part of a Europe that can stand more firmly on its own. That makes it meaningful to start locally and explore how we can develop and produce smarter together with others,’ Johansen says.

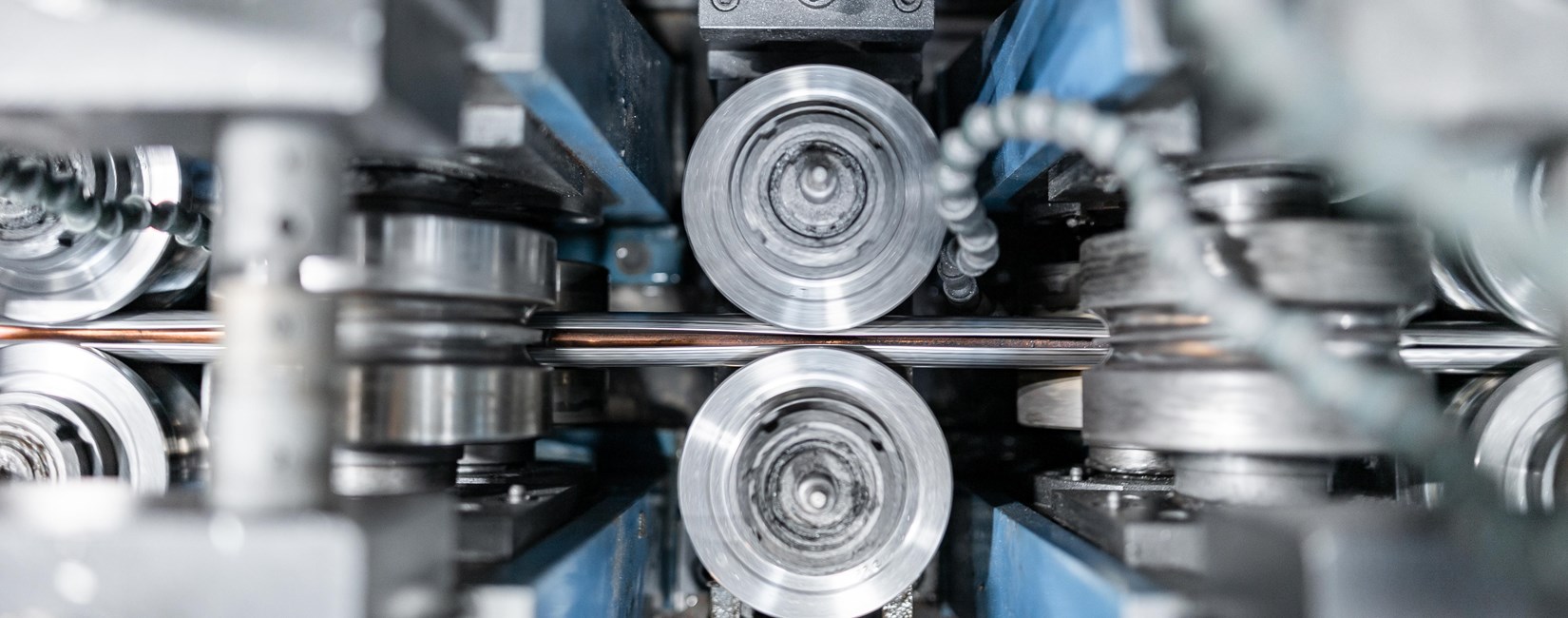

Sole currently specializes in the production of heat exchangers and piping systems.

We produce our own pipes and can bend them into any shape. This is something we believe may be relevant to others in the network. We have both the technology and production solutions that can add value in various contexts,’ he says.

Exploring New Market Areas (1)

Exploring new market areas

Membership in the Kongsberg Technology Cluster may also open doors to new industries and areas of expertise.

We want to diversify. That’s why we aim to explore new market areas and are willing to invest in new production equipment to meet the needs of potential customers. Right now, we’re part of an exciting project led by the cluster that focuses on 3D printing, also known as additive manufacturing, and circular economy. We’re looking into the possibilities of sourcing local raw materials, combined with local production and recycling, in collaboration with companies such as Uvdal Maskinfabrikk, GKN Aerospace, and SINTEF. There’s serious expertise in this collaboration and high ambitions behind it,’ Johansen says.